Rachel Whitney, Curator

Sapulpa Historical Museum

This week in Sapulpa history, on June 2, 1905, it was announced that Sapulpa Pressed Brick Company was doing well, in fact, it was the “largest in the Territory.”

“Sapulpa has, in the Pressed Brick Plant, an industry of which she is proud.”

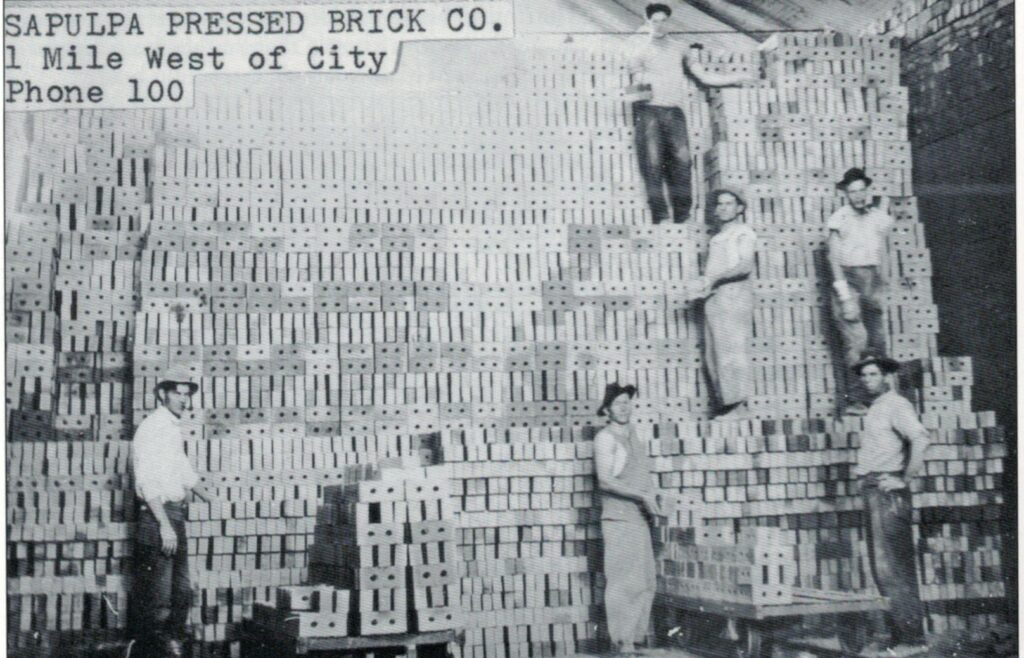

At the time, the plant produced “outside walk brick, common building brick, and dry pressface brick.” And with 35 to 45 employed workers, their payroll averaged to $2,000 per month*. It also produced between 30,000 to 60,000 bricks every day, with a shipment of three cars on the train a day.

*Note: the average $2,000/month or $24,00/year would be with today’s inflation around $60,000/month or $720,000.

The plant was said to be the best one in the Territory. With 55-acres of land used for the plant, there was also a “bank of shale, just west of the works, is probably the best that can be found any place.*” It was located on the west side of town, just past Independence Street, and on the southside of the Frisco tracks.

*Note: shale is a soft, fine-grained rock that is a mix of flakes of clay and other minerals. It is the most common sedimentary rock. It is often called mudrock; often used to make bricks.

The Sapulpa brick was well known in the neighboring areas. “They shipped all over Oklahoma, Indian Territory, and Texas. The demand for them is becoming larger every month.” It used the most advanced kiln and machines in their time.

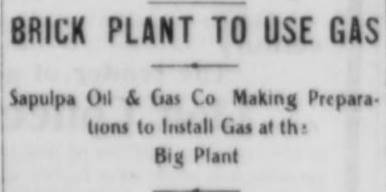

In July 1905, it was announced that the plant would start to use gas, instead of coal. “The Sapulpa Pressed Brick Plant will soon be burning gas at their big plant. They use lots of fire and the gas will make it much cheaper. After gas has been put into use the plant cna make brick just a little cheaper than any other in this vicinity.”

In December 1905, the Sapulpa Pressed Brick was among the highest employed facilities in the city. The article listed businesses and the number of employees under the organizations’ name. The Central Light & Fuel Company listed having 6 to 80 employees. While Sapulpa Pressed Brick Co. listed having 65 workers in their facility. “The pay roll of the Frisco Railroad alone in Sapulpa reaches from $60,000 to $90,000 per month. Frisco Shops had 750 employees.*”

*Note: In 1905, $60,00 and $90,000/month or $720,000 and $1 million/year would be in today’s inflation as $2 million and $3 million/month or $24 million and $36 million/year .It also listed “train dispatchers, train masters, Harvey House, railway station service, yard men and depot truckers, yard clerks,” and many other rail related jobs.

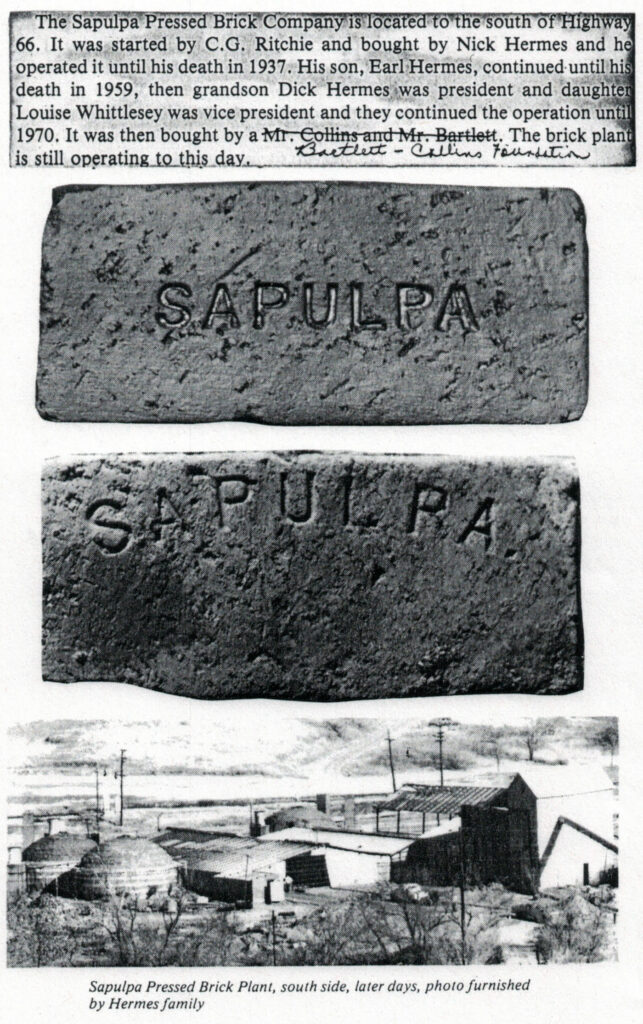

The Sapulpa Pressed Brick Company was incorporated in 1898, with J. Boyd, Fred Pfendler, and Webster Wilder. Later the company was sold in 1902, with J.A. Daly, Fred Pfendler, C.G. Richey, and F.M. Daly.

The plant would become the Sapulpa Brick and Tile Company, owned by the Hermes family. With ample supply of shale, the company would run until late 1970s and early 1980s. It would be a modern electrified plant, still among the most efficient in the state. It would ship to Arkansas, Minnesota, Nebraska, Tennessee, Texas, Colorado, and Louisiana.

(Sapulpa Light, June 2, July 21, December 29, 1905; Democrat News, July 4, 1957; “Made out-a Mud,” Luke Robison)