Rachel Whitney, Curator,

Sapulpa Historical Museum

Frank and Bessie Alice with their three children: Alberta Victoria, Kingley Edward, and Violet May, had finally arrived in Sapulpa. After a short train ride, the family moved from Chanute, Kansas. The family had hoped on the Sante Fe railway from Chanute to Claremore, Oklahoma. From there, they took the line to Sapulpa via the Frisco railway.

The travelers entering Sapulpa from the east on the Frisco would see a large sign greeting them to the Creek County capital. This was the first memory of the town of Sapulpa for the Bostock family, as well, when they arrived at the Sapulpa station in July 1913.

The Bostock Family: 424 South Independence circa 1915; Violet May, Kingsley Edward, Alberta Victoria, Bessie Alice (mother),

Frank (father).

“What a thrill to see the sign at the station: ‘Sapulpa, the Oil City of the Southwest.’”

Many families traveled to the new state added to the United States in hope for a new beginning, a new place to start a family, bring a business, and gain momentum of the growth in the state. As people moved to the area, more business began to grow, and as the businesses grew, more people arrived to work and consume. The resources found in Oklahoma were one of the many reasons for many families and businesses to ride the train to the area.

“Pressed, blown, and flat glass have been produced in Oklahoma over the hundred years from 1904 to 2004. The glass industry exemplifies a manufacturing opportunity that developed in the early twentieth century because raw materials were locally available. High-quality glass sand, with few impurities and high silica content, occurred in abundance in southeastern Oklahoma in the Arbuckle Mountains near Roff, Sulphur, and Mill Creek and in the northeast near Tahlequah, as well as in other locations. In addition, natural gas, discovered after 1900, provided an abundant fuel source. These criteria, coupled with a ready supply of labor, made the glass industry a small-manufacturing success story. The earliest glass products were made in 1904–10 by Great Western Glass Company of Bartlesville. Glass sand was imported from other states until a commercial glass-sand mine opened near Roff in 1913.”

The Bostock family arrived in town and moved in temporarily to their new home, a room at the St. James Hotel, as their new house was being constructed at 424 S Independence St. The family moved from Kansas for Frank’s new job and its new location.

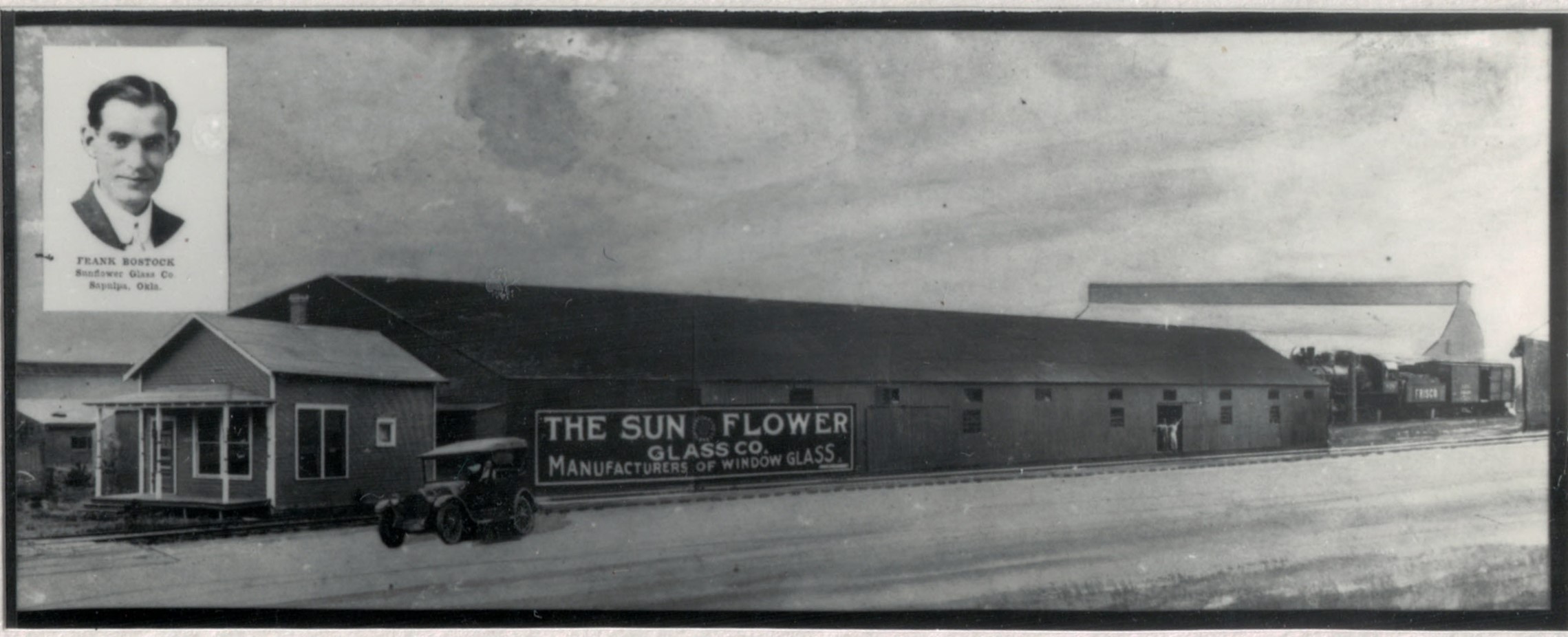

Frank Bostock was the co-owner of the Sunflower Glass Company at Coffeyville, Kansas, which began in 1903. Incidentally, a family story noted that Frank’s older brother, Edgar, achieved some fame when he did the glasswork that created the original torch on the Statue of Liberty.

In September 1912, city commissioners of Sapulpa and “Taxpayers League under the leadership of chairman John F. Egan” and the Commercial Club accepted the Sunflower Glass Company proposition – to move operations to Sapulpa.

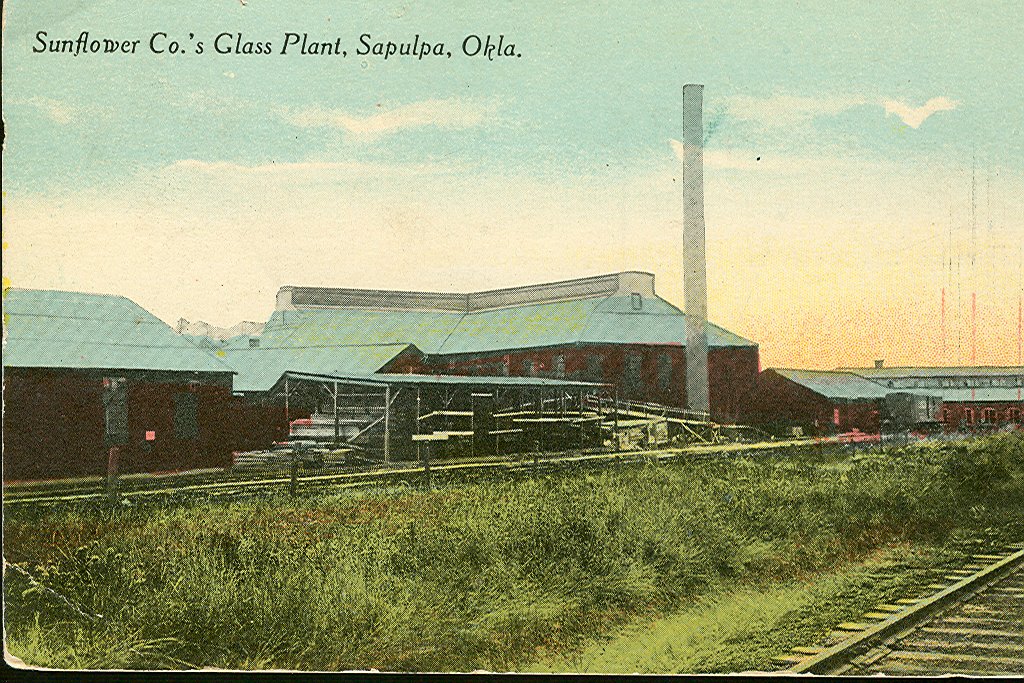

In February 1913, just months before the Bostock family moved to town, the Commercial Club furnished the plant with $18,000 and a four acre site. The four acres was to be located between the old foundry and the brick plant*. It was expected to be in operation in just six months.

*Note: the $18,000 would be just over a half a million dollars today. The Sunflower was located at 800 W Dewey, where the Sahoma Motel once stood or about just west of Days Lumber.

It would employ 175 men, and could be the largest payroll in Sapulpa – other than the Frisco railway.

“The plant will be a 36 blower institution. Window glass will be the speciality.” The Sunflower company was known for their hand-made glass.

In a few short months, another glass company would be just down the road. The Schram Glass Company had been working with the Commercial Club and finally accepted to come to Sapulpa. Sapulpa would furnish a site and when the plant was in operation give the company $25,000. This plant would be one of the largest in the country and would cost $100,000 in buildings alone. It was originally planned for north of town, but would be located west of town at the end of Dewey*.

*Note: the $25,000 and $100,000 would be $750,000 and $3 million today. It was located at “1 mile west of the city,” or where Tee Pee Drive-in Theater is now.

This would give the town of Sapulpa four glass companies: in 1912, Premium—which would later become Liberty Glass—for commercialware, Cheyenne—which would become Bartlett-Collins—for houseware, and in 1913, Sunflower for window panes, and Schram for fruit jars.

With businesses growing, the street car had to connect the townspeople to the factories. The street car company began to work on extending their line to the new Sunflower and Schram glass plants west of town at the end of 1913, early 1914.

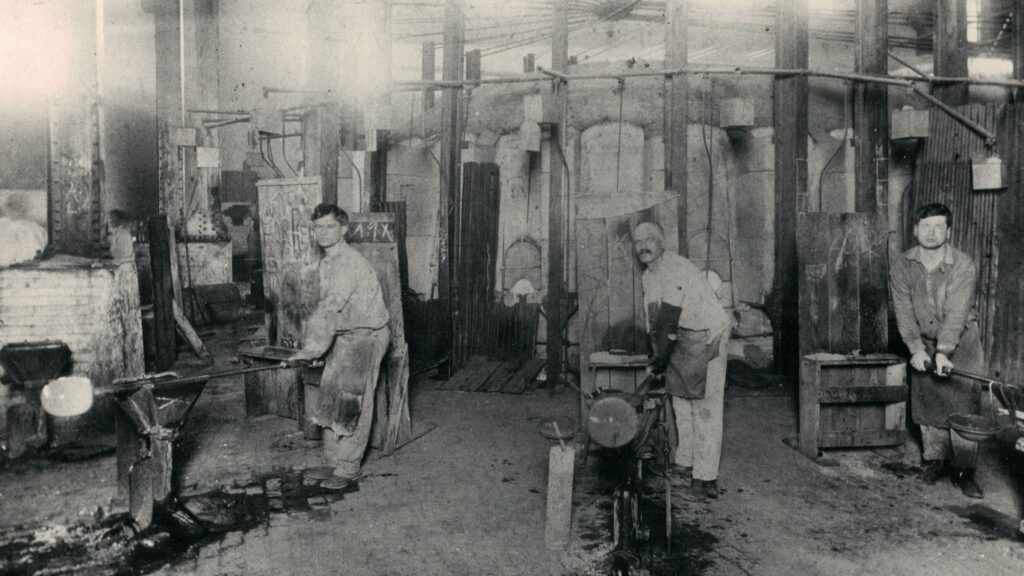

Sunflower Company produced only window or “flat” glass. Its method of production was labor intensive. A skilled glass blower wielding a “blow-pipe” would gather a blob of molten glass from the furnace; and blow into it to form a globe shape. Swinging and blowing the globe into the pit, a long cylinder of glass was produced. This cylinder was then cut on one side, lengthwise, and sent to the “flatting room.” Rollers and heat stretched the cylinder until it was reduced to a flat sheet of glass. Next, the glass was sent to the “cutting room,” where sheets were cut to various window sizes.

This form of window making can be identified by its “wavy” appearance.

By 1915, ups and downs at the Sunflower kept the business and workers busy. Both Sunflower and Schram would close temporarily for the weather being too hot to work in the factory. Glass plants at the time worked very seasonally and would shut down when inventory was full. A lot of these workers would then go back to their homes in other states and wait for the plants to reopen.

But sometimes the plants would close for accidents and leaks. For a couple of instances, this week in Sapulpa history, a young worker was killed in an accident at Sunflower in 1916, a break in the gas line from Central Light & Fuel Co. shut down a few businesses, including the Sunflower, in 1914.

After the 1915 summer break, Sunflower reopened for a high demand. Due to the war, window glass was in great demand on the east coast. Men were returning to Sapulpa from their homes in other states and the town began filling back up.

In addition, this week in Sapulpa history, on December 15, 1915, it was announced that the Sunflower was working at capacity and still could not keep up with the demand for window glass. The war had disrupted the window glass business in Europe, as well. Most European glass plants were in Belgium or northern France; these would be occupied by the Germans in World War I. It was thought that even after the war, American window glass would be in high demand as it would take some time for the European plants to rebuild and start production.

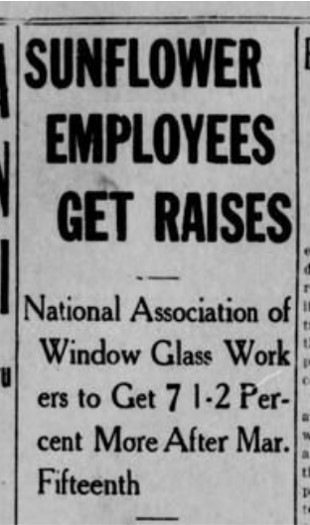

In March 1916, the workers at the Sunflower were given a 7.5% raise. Window glass manufacturers and the unions had agreed on a raise due to the excellent year the glass industry was having*.

*Note: In a 1915 article, it listed that for Sunflower, 190 men were employed at the plant and it stated the monthly payroll is $15,000 (or $444,000 today) . If every worker had the same wage, everyone earned $79 a month (or $2,350 today), which would be about $20 a week (or $600 today).

As The Great War raged on, patriotic fever ran high and everyone tried to show their support for the war in Europe. The Sunflower Glass had installed a 40’ flagpole on top of their warehouse. A ceremony rang in the raising of the 7 feet by 14 feet American flag. The fire department delivered the flag in their fire truck.

“This is Sunflower day. Not in the sense it would be taken in the neighboring state of Kansas, but as it is fully appreciated by the employees of the Sunflower Glass plant.” Frank Bostock, the workmen “of about 200 employees of many nationalities,” and townsfolk “were present to witness the inspiring sight.”

At the end of the war, expansion began for the glass plant. A new glass plant had been organized by Frank Bostock, Fred Lucas of Sapulpa, U.G. and C.H. Baker of Okmulgee. They had purchased a plant in Augusta, Kansas and they had plans to move it to either Okmulgee or Sapulpa. The site selected would depend on what kind of inducements could be obtained. This company was formed as the United Sash and Door Company. It would join the site of Sunflower.

This week in Sapulpa history, on December 11, 1924, it was announced that the company known for its hand-made glass would be purchasing machines.

“Sunflower Glass Plant Will Install Machinery and Increase Capacity,” read the headline.

“The big Sunflower Glass Company Plant, which has been idle for more than a year, will resume operations within the next three months, according to the announcement of President Frank Bostock. Realizing, some time ago, that hand-made glass was obsolete, the management of the Sunflower began to consider the advisability of installing machinery here. This will ensure uniformity of the product, which was impossible by the hand method, and Sapulpa plant will furnish much of high grade plate glass that will be used in this county in the future.”

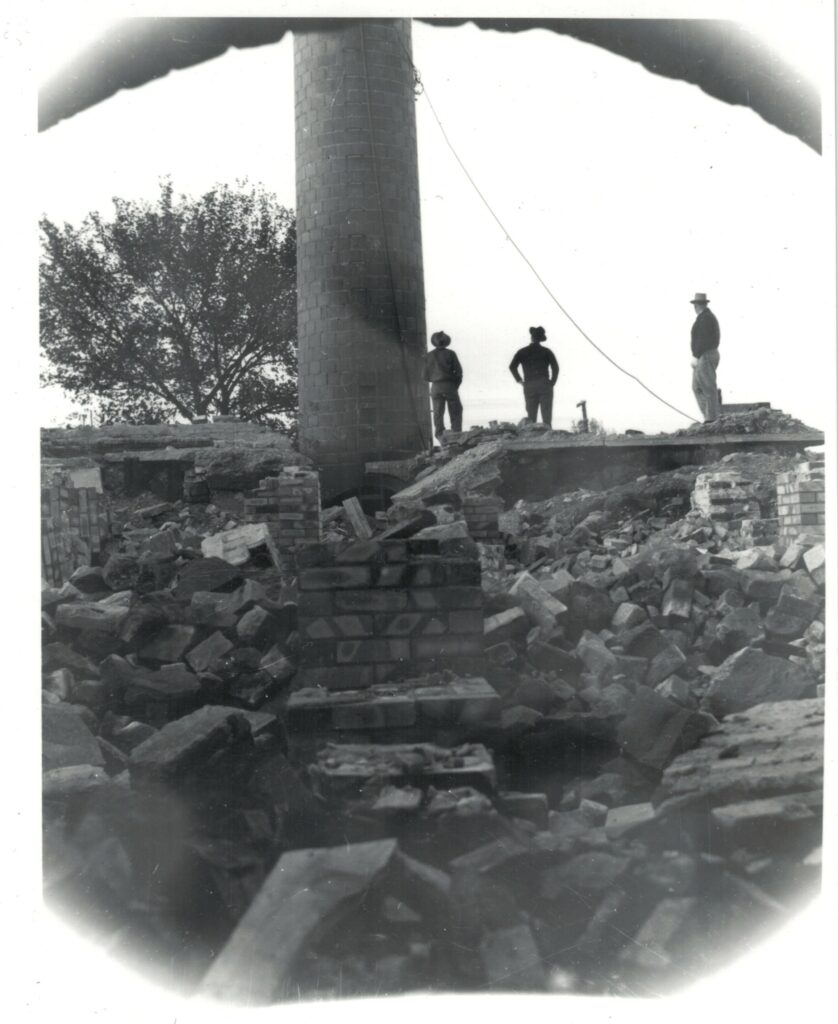

The Sunflower was planning on selling $35,000 of stock so that it could buy machinery to build one of the largest plate glass plants in the southwest. It had been closed for two years because there was not any demand for hand-made window glass.

In 1925, the Sunflower began full operations with its new equipment. It would now employ 150 men. But the cost of the machines were too much, and the plant struggled to make ends meet. Sunflower remained in operation as the company umbrella name, but operated as the Victory Window Glass. By 1927, Fred Bostock and Frank Lucas announced that the Baker Brothers of Okmulgee had purchased over 50% of the stock.

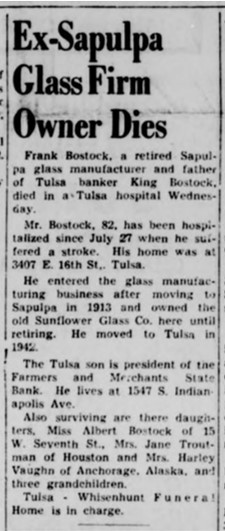

By December 1938, the plant sat vacant for nearly six years until the property was sold to Harding Glass of Fort Smith. Harding paid $4,534 for the plant, which included $2,134 in back taxes.

The Sunflower ceased operation in 1932. Frank Bostock passed away in August 1959.

(Sapulpa Weekly Light, September 6, 1912; Creek County Republican, February 28, 1913, October 31, 1913, December 11, 1914, January 29, 1915, December 15, 1916; Sapulpa Herald, October 26, 1914, December 16, 1915, February 28, 1916, May 26, 1916, April 14, 1917, December 11, 1924, December 16, 1924, May 6, 1925; County Democrat News, December 11, 1924; Democrat News, August 27, 1959; Coffeyville Area Chamber of Commerce; National Income and Its Purchasing Power; OMNI Calculator; Oklahoma Historical Society; Academic Accelerator)

Subscribers to the Timeloop+ got this news first. Don’t miss out and become a subscriber for just $6.99 a month! Sign up today.