Route 66 might be the most famous street in Sapulpa, but Hobson Avenue is starting to get some much-deserved attention after the grand opening of James Calley Brewing Company this week.

James Calley Brewing Company—an amalgamation of the names of the owners Jim Dilley and Randy Calley—is not only a Sapulpa standout for being the first and only commercial brewery in Sapulpa but for a production process that promises to reduce waste and contamination, and improve the efficiency and quality of the beer they make, all the way to the glass it’s poured into.

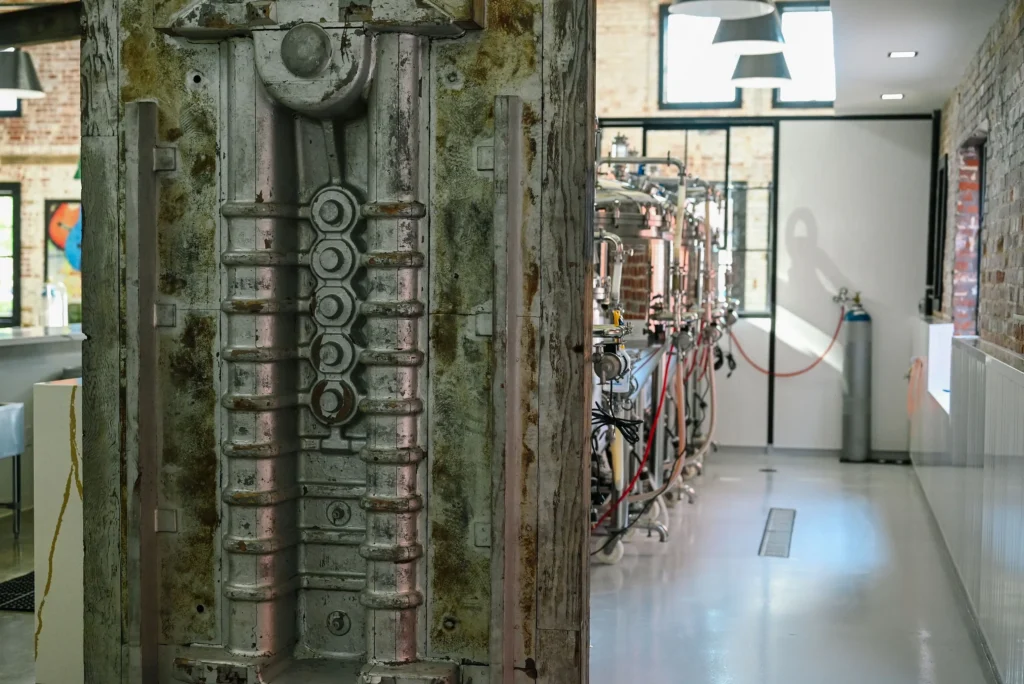

“In a traditional brewing environment, you do your mash and your boil, and then they transfer it to a fermentation vessel,” Dilley explains. “When it’s done with that, they transfer from there to what they call a bright tank, where they let it settle out for a period of time—It could be a couple weeks, it could be a week, it could be a month, that depends on what they’re making.”

“When that’s done, the next step is to transfer it again to either a keg or a bottle or a can or whatever else they’re going to deliver out to wherever it’s being served, and then ultimately it goes to the consumer. Every time you transfer a beer from this vessel to this vessel, to this vessel, and ultimately to the consumer, there’s a risk of contamination. All this has to be cleaned. It uses a lot of excess water. It uses a lot of excess cleaning components.”

“For our system, we do everything in this vessel, and when we’re done, everything in there is sanitary; it’s brought to a boil. It has steam. We lift our grain colander out of it and set that aside. Then we cool this down to a certain temperature. We put our yeast in there, we put the lid on, we ferment right out of here, and then when this is done, we wheel it over behind the bar, we hook it up to a chilling system, and we hook it up to our taps, and it comes right out of there to your glass.”

Dilley says that their process not only eliminates most of the waste and excess cleaning, but it also improves the quality of the beer. “There never any transfer from the initial boil,” he says. “So that beer that’s coming out into their glass has never touched oxygen the entire time. There’s no contamination. They’re going to have the freshest beer they’ve ever had,” he said.

The process sounds so amazing, it’s a wonder that every other brewer hasn’t replicated it. Dilley says most of the craft brewers don’t have the space, and most of the big commercial ones have a process that relies on large quantities and prioritize volume over the quality you’d get in a smaller, more managed batch.

Dilley made it clear that James Calley Brewing Company has no aspirations of ever getting into the retail and distribution side of the business. “We’re not trying to be the next Coors,” he said. “The craft brewery business got away from what they were good at, and that was a community place to hang out, and most of your customers live within about five miles. The breweries that have tried to go retail and gone distribution, a lot of them gone out of business cause they can’t compete. What made the craft brewery business special, and why they all survived, is they had something unique.”

Randy Calley says he believes the brewery will become a destination spot on Route 66. “It’ll be like, Michael Jones (Gasoline Alley Classics), people coming through, and he’s sending people here, and we’re sending people there. It’s a community thing. It gets back to that Irish pub that he was talking about. At five o’clock in the afternoon, entire families show up at the Irish Pub. I mean, the kids, the grandmothers, the dads among everybody shows up. That’s their community hall, and that’s what craft beer is to me—giving back the community by coming up with something unique.”

So far, it appears that the goal being well achieved. On a Thursday evening, nearly every table is full, and many with children. The kitchen, serviced by former “Chuck-It Hot Dog Girls” Amanda Stephens and Jen Wagner, is cranking out dishes regularly, including a hot new Reuben Sandwich, which is reportedly selling out every day.

Dilley says that having Stephens and Wagner man the kitchen is not an accident, and just part of the intention they had with the kitchen from the start.

“We wanted to have something that was unique, that you could not get anywhere else,” he said. “So we’re getting our chicken wings and our smoked chicken that we use in our recipes are from a custom butcher from one of the Indian nations. Our bratwurst, our hot dogs, our pastrami that we’re using in our reuben sandwiches is from a custom butcher in the upper Midwest. And so the stuff that we’re doing in the kitchen. It’s one more reason for people to come here, because they can get something here. They can’t get anywhere else.”

Calley added that they take as much pride in the way they get the ingredients for their beer as they do in the way they produce it.

“Our malt is all grown in the United States,” he said. “And a big majority of it is going to what we call ‘regenerative’ farming. They pay the farmers more money to not till the soil, to have cows to come on for a year and graze on that property. That’s regenerative, it’s putting the nutrients back in the soil. That alone is making a big difference in erosion and everything else. I didn’t realize that was that big a deal until I got into it, and that’s kind of cool that we’re contributing with that.”

The History of the Building

Located at 117 E Hobson, the building was formerly the Anderson Machine Shop, but if you go back to the beginning, it was built in 1915 as a livery stable, according to owners Jim Dilley and Randy Calley.

“I always tell them it was a parking garage for horses,” Dilley said. “That lasted probably for maybe 10 years, because the automotive industry started firing up. There was a short period of time where it was empty. And then for probably the next 50 years or so, the building was primarily used for oilfield supply. Then the Anderson family bought it in the early 80s, and he was a machinist. He owned it for the better part of 35 years, till I bought it in 2019.”

After Dilley had purchased the building—but prior to its renovation—it was also used in the filming of an episode of “The Story Behind the Story,” a TV show based on the wildly popular podcast “The Way I Heard It,” starring actor Mike Rowe, who also narrated the show. The episode starred Hunter Cates, who had appeared in several plays at the Sapulpa Community Theatre, and was a retelling of the story behind the creation of the modern-day fake snow seen in Hollywood, bringing about a large technical achievement in a movie that began as a flop but went on to be immortalized in holiday cinema.

Dilley says he hopes the renovated building will not just be a place for locals to hang out and enjoy, but also act as an example of what can be done with the buildings downtown.

“We had a lot of people come in and look at this building and go, ‘we need to do a building like this,’ or, ‘I already own a building I wasn’t sure what I was going to do with it, I think I’m going to build a bistro restaurant.’ I think it’s given people some perspective on what you can do with an old building. Because really, there are a lot of buildings downtown that have been redone, and nothing’s been done like this.”