In 1916, W.F. Wickham and his wife, known by friends as “Grandma and Grandpa,” settled on a farm north of Stroud, Oklahoma. With five daughters, Ersa, Gertrude, Mable, Laurene, and Edith; along with three sons, Roy, Carrel, and Kenneth.

The Wickhams bought cattle to stock the farm. The money was obtained through a loan at a Stroud bank. However, when the note came due, economic conditions had deteriorated and the market for cattle was at such a low level that their banker refused to take cattle as payment for the loan.

“Grandpa” Wickham was known for his honesty and resourcefulness. Wickham wanted to pay his debt so he approached the banker with a business proposal. He told his banker he would butcher the cattle, sell the meat, and pay off the loan with the proceeds. This clever idea turned out to be successful. The banknote was paid in full and at the same time, Wickham made a meager profit. Thus began the Wickham Packing Company.

Through hard work and diligence, the Wickham family was able to accrue several thousand dollars which they used to buy out a small packing plant in Drumright. The Wickhams operated this facility until the oil boom ended in 1918.

Citizens in Bristow convinced the Wickhams to start a plant in Bristow. Money obtained from both local banks allowed the Wickhams to build a new plant with a cement floor south of Bristow. This plant was profitable but disaster struck in July 1937, when a fire completely destroyed it. Since the building was outside the city’s fire coverage, the plant was not covered by insurance, resulting in a total loss. A temporary plant was set up in the Standard Packing Company building in Tulsa, Oklahoma to service their many loyal customers.

Wickham Comes to Sapulpa

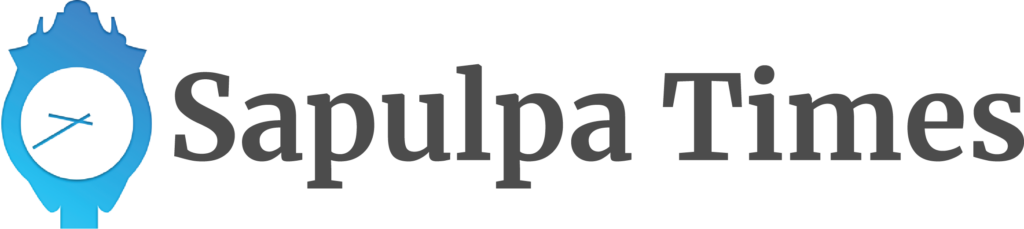

Sapulpa business leaders heard about the Wickham reception and business acumen and made a “substantial” offer to entice them to put their operation in Sapulpa. The Sapulpa plant opened with a mere $25,000 in capital on January 1, 1938, at 519 West Dewey Ave. Hundreds of thousands of dollars were spent on capital improvements. It was a turnkey operation. The animals were slaughtered, processed, and packaged at the Sapulpa location. The Wickham Packing plant was considered one of the most outstanding and modern independent packing plants in the Southwest.

Wickham Packing Company subsequently established a plant in Ada, Oklahoma, purchased a slaughtering facility in Longview, Texas, and bought a 460-acre farm for raising and feeding cattle.

In May of 1956, The meat industry magazine, “The National Provisioner,” wrote a feature story about The Wickham Packing Company. When alluding to collection and credit losses, the article stated that the company had $3 million in sales in 1955 “without a single loss.” The magazine went on to say that President Roy Wickham and Vice-President Charles Cecil Hamilton made a wise choice by relocating to Sapulpa after the loss in Bristow. A detailed description was given of all the state-of-the-art equipment the plant possessed. It is interesting to note that the article mentions that only 1 percent of total sales was allocated for advertising.

According to Charles Roy Hamilton, who became vice-president of the company, told the Sapulpa Times that by the 1970s, there were approximately 120 employees. Many Sapulpa residents recall working there.

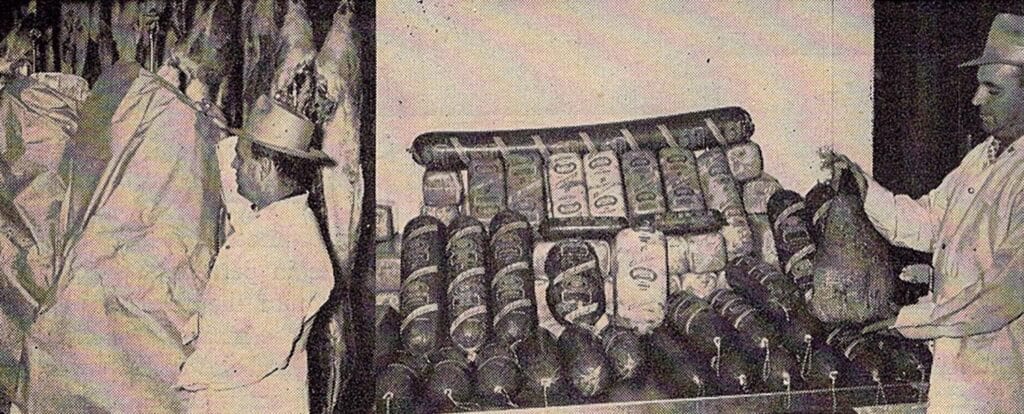

Bill White, who worked in the sausage kitchen in the summer of 1966, said “It was a pretty good job, but I smelled like bologna.” Rick Tyler said his dad George went to work there in 1939 as a “boner” for 35 cents an hour. Jim White was a route driver. “I worked every route they had,” he said. “Hard, heavy work, but I was young, and I thought, tough. Used to carry those sides of beef up and down stairs. No wonder I [eventually] had lower back surgery.”

Jack Isbell said he worked at Wickham’s the summer of his senior year in the maintenance department. “I learned how to refurbish iron meat hooks with a forge, an anvil, and a hammer, and operate and maintain a large water softener and other plant maintenance.” Isbell says that he unloaded cattle trucks, “chased a cow or two, and repaired the cattle pens. There was always something to be maintained throughout the plant.”

After high school, Isbell continued to work there for a few more years, putting up orders. “Travis Belk was in charge of the order room and was a great work guy to work for,” Isbell said. His next job was blocking hogs, then he moved to the beef cooler room hanging beef carcasses on a rail system, and learning to grade beef from the feral Meat Inspector, Loyd Neal. His final job was driving a box-type delivery truck.

Sandra Ledgerwood worked in what was called “Wickham’s Weiner Room.” “I was the only woman that worked in the cutting room.” She also put up orders and helped bag hams and package bacon. Her father, Travis Belk worked there and was, according to Ledgerwood, “A top-notch salesman.”

Sapulpa shoppers frequented Jones’ Supermarket just to buy Wickham meat. My father—who was at one time a butcher himself—was very selective about purchasing meat. He bought most of his meat at Jones’ because of its quality.

By the 1980s, things were looking dour. Dwindling sales, thanks to the demise of mom-and-pop grocery stores—which made up most of Wickham’s, primary customers—made the end inevitable. Wickham’s Meat Packing Co. closed in 1986. Another once-thriving family-owned business is relegated to the annals of local history.

I wish to thank Charles Roy Hamilton, who was vice-president of Wickham Packing Company until the plant closed, for his assistance in this story.